TekniPlex Healthcare’s Holistic Approach to Sustainability

Even as COVID-19 wanes, the plastic pandemic continues. Consumers and organisations are aware of the need for a circular economy, particularly in the consumer goods and healthcare sectors, which are responsible for significant levels of waste. Considering healthcare’s unique challenges and patient health priorities, how can the industry work toward more sustainable packaging solutions, as well as elevate eco-consciousness across the entire value chain?

For proper context, it must first be understood that, in the overwhelming majority of circumstances, recycled plastics are not considered “pharma-grade,” meaning they cannot come into contact with medicines in any form, including pills, powders or liquids. This cautious approach is reasonable, since the healthcare sector is producing and packaging products whose sole purpose is to save lives and improve patient outcomes. The processes used to recycle plastics often require caustic, sensitive substances that could interfere with the purpose of pharmaceuticals.

Producing sustainable packaging for pharmaceuticals

Many industries are now taking into equal consideration product protection, customer experience and sustainability into their packaging practices. The healthcare sector, for good reason, mandates firm guardrails that ensure product efficacy and patient safety remain paramount.

For a materials sciences solutions provider like TekniPlex Healthcare, based in Pennsylvania, US, sustainability is viewed through a more holistic lens. With certain single-use plastics a necessity for the time being in the healthcare sector, efforts such as waste reduction, repurposing scrap for non-pharma-related purposes, and extending product life spans all serve to reduce ecological footprint. Always, the goal is to improve the health of the planet without compromising the health of the patient.

Companies like TekniPlex Healthcare, then, must run an especially tight sustainability ship. And fortunately, breakthroughs in materials science may soon make for even smoother sailing.

Chris Qualters, CEO of TekniPlex Healthcare, discussed the materials science breakthroughs that improve sustainability characteristics, as well as recent technological advancements with the promise of bringing pharma-grade recycled plastics from aspiring to actual.

Qualters first emphasised that uncompromising patient care and better outcomes are the overarching goals of healthcare sector operations. It is the starting point from which any long-term sustainability solution considerations must begin.

“On the healthcare side of the business, we're providing materials science solutions to help bring better therapeutic and interventional devices, as well as pharmaceuticals to the market that improve patient outcomes while ensuring they get to the point of patient care safe and sterile,” Qualters says.

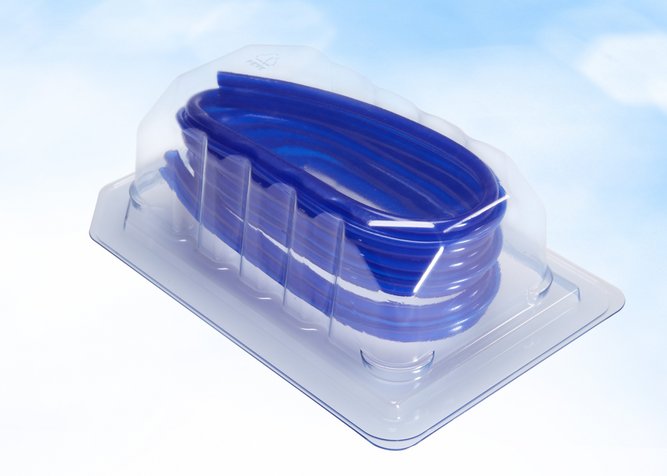

He pointed out that the company’s material sciences expertise has led to TekniPlex being among the first to offer a complementary series of polyolefin blister films, Tekniflex® COC and Tekniflex® ECO, that earned high recyclability scores.

TekniPlex is also helping lead the charge to utilise chemically recycled resins to produce films for the packaging of pharmaceuticals and medical devices. This incremental yet game-changing effort takes resources, R&D and expertise that stands on the shoulders of the long march toward a circular economy.

“We're focused on improving outcomes and making lives better. But being mindful that the overall purpose of what we're trying to do with our materials science solutions is to make the world a better place, it's important we continue to find ways to advance the sustainability effort,” explains Qualters.

ESG takes precedence at TekniPlex

As an organisation that is centred on ESG, TekniPlex is committed to reduce the use and consumption of certain materials and energy, as well as continuing to advance the sustainability of its products .

TekniPlex Healthcare’s advancements in sustainability are assisted, in part, by the efforts of its sister division, TekniPlex Consumer Products. The latter services sectors such as food & beverage and personal care in which consumer demand is driving sustainability, and where implementation guidelines are understandably tight but not quite as tight as healthcare. Developing recycled and recyclable packaging for food products allows the company to reduce its carbon footprint in a sector sometimes affected by overpackaging. It also helps better inform its activities on the healthcare side of the business.

While there have been meaningful advancements in sustainability in healthcare, there are more opportunities to explore in this area. Qualters believes that aiming for 100% circular packaging across the healthcare sector is the best mindset to have.

“In bringing sustainable materials and processes forward, even though at the current time there isn't necessarily a path to start bringing materials out of hospitals and clinical settings to recycle them, the industry is saying ‘let's be ready.’ Let's look at these materials science solutions today. Let's understand what some of the challenges are. Let's work together, innovate, and ensure the materials are ready for recycling.”

- How Tenaris & Tata Steel are Sustainability Champions AgainSustainability

- Tetra Pak: Consumers are Driving Plastic Packaging ReductionSupply Chain Sustainability

- Top 10: Women in Sustainability in the UK and EuropeSustainability

- E.ON Next: Customer-Centric Approach Drives Business SuccessSustainability